|

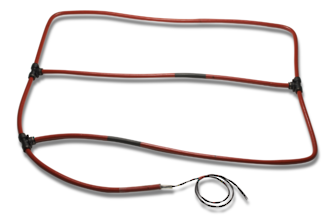

Base course buried

|

Base Course Buried preformed inductive loop

|

9.5mm Inductive Loops - Model CG9.5MM

Conduit- Highly abrasion-resistant Polyurethane alloy cover

- High tensile strength braided synthetic yarn reinforcement

- Good flexibility over a wide temperature range

- Minimum impact pressure of 3000 psi (20,680 kPa)

- Nylon alloy core tube

- Superior resistance to oil, gasoline, salt, moisture and impact

- Max. o.d. of 3/8” (9.5 millimeter)

Connection – Loop Head to Loop Lead-In

- High tensile strength / tenoerature self-locking Polyethylene “T” connector to connect the loop head to the protected lead-in (No wire splices)

Wire

- Loop wire is 20 gauge silver coated with Teflon jacket, stranded, single conductor wire.

- Number of turns to be determined by engineer or factory and will depend on loop size, loop depth, presence of reinforcing steel and other special factors

- Lead-in wires shall be machine twisted at a minimum of 8 twists per foot (30 cm).

- One continuous wire shall be used to manufacture the loop and lead-in, no splices shall be allowed.

- Extra wire shall be incorporated throughout the conduit by means of the “Z” method to compensate for pavement movement.

Miscellaneous

- Loop and lead shall be filled with a flexible rubber self sealing emulsion to prevent moisture entering the conduit and prevent false calls from movement of the wire within the conduit.

- Preformed loops shall be commercially manufactured.

- Quality control of the end product shall be performed and passed as specified in the Preformed Inductive Loop (P-ILD) Handbook V.2.4 and be submitted to the end user.

- Loops shall be individually marked as to the direction of the wire turns.

- Preformed loops shall have a 15 year minimum manufacturer's guarantee.

16mm Inductive Loops - Model CG16MM

Conduit- Highly abrasion-resistant Polyurethane alloy cover

- High tensile strength braided synthetic yarn reinforcement

- Good flexibility over a wide temperature range

- Minimum impact pressure of 3000 psi (20,680 kPa), minimum burst pressure of 1400 psi

- Polyurethane alloy core tube

- Superior resistance to oil, gasoline, salt, moisture and impact (class A)

- Max. o.d. of 5/8” (16 millimeter), max i.d. 3/8”

Connection – Loop Head to Loop Lead-In

- High tensile strength / high heat Polyurethane compression “T” (No wire splices)

Wire

- Loop wire is 16 gauge tffn / thhn / thwn stranded, single conductor wire.

- Number of turns to be determined by engineer or factory and will depend on loop size, loop depth, presence of reinforcing steel and other special factors

- Lead-in wires shall be machine twisted at a minimum of 8 twists per foot (30 cm). 10+ for special applications e.g. bicycle loops.

- One continuous wire shall be used to manufacture the loop and lead-in, no splices shall be allowed.

- Extra wire shall be incorporated throughout the conduit by means of the “Z” method to compensate for pavement movement.

Miscellaneous

- Loop and lead shall be filled with a flexible rubber self sealing emulsion to prevent moisture entering the conduit and prevent false calls from movement of the wire within the conduit.

- Preformed loops shall be commercially manufactured.

- Quality control of the end product shall be performed and passed as specified in the Preformed Inductive Loop (P-ILD) Handbook V.2.4 and be submitted to the end user.

- Loops shall be individually marked as to the direction of the wire turns.

- Preformed loops shall have a 15 year minimum manufacturer's guarantee.

For installation in the base course prior to seal.